Dowels

Secure fastening technology for every wall and every building material

Whether concrete, brick, aerated concrete or insulating material: with the right anchor, every fixing is secure and reliable. In professional electrical installations, choosing the right anchor is crucial - for the load-bearing capacity of the entire construction and for your safety. At WATT24 you will find a wide selection of high-quality wall plugs for almost all building materials and fastening types.

- Comprehensive advice & support

- over 10,000 articles in the shop

- Shipping in 24 hours

- thousands of satisfied customers

KATHRIN BRANDT

Employee Purchasing from TroisdorfGreat advice and friendly service. I was helped immediately and competently with any questions. Gladly again.

OMAR NASER

Office Manager from Frankfurt a.M.Goods are well packaged and arrive safely, which is important to me. My mail was answered immediately.

RAINER SEIDEL

Master carpenter from WiesbadenHad to replace a lamp, but the same was no longer available. Great advice, found a suitable replacement and delivered it quickly.

What do you need wall plugs for?

Anchors make it possible to permanently fix screws, bolts, anchor rods or other fastening elements in wall materials that would not be strong enough on their own. They ensure a non-positive connection between the screw and the building material. Whether fixing lights, cable ducts or switch boxes - with the right anchor, you can achieve the necessary load-bearing capacity and load-bearing capacity.

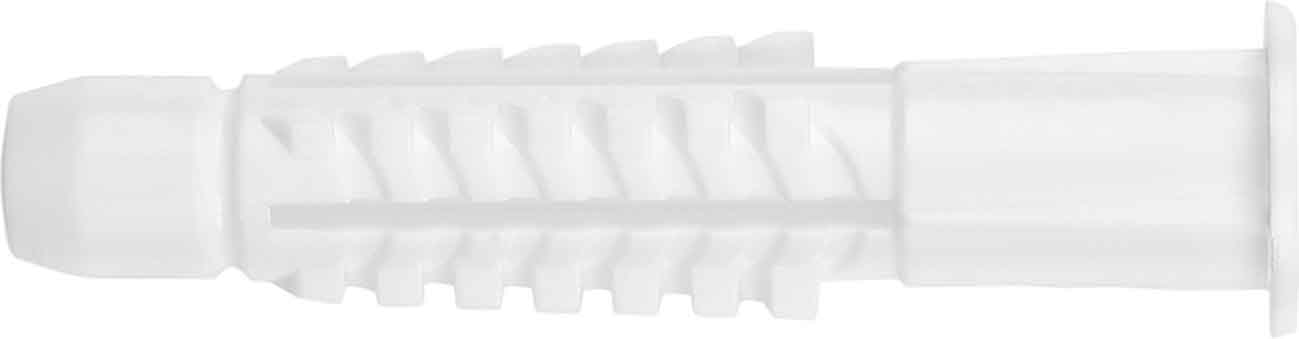

Depending on the application and wall material - such as solid building materials, hollow ceilings or insulating materials - different types of wall plugs are used. A distinction is made according to material (e.g. plastic plugs, metal plugs, brass plugs), shape, load-bearing capacity and the type of fixing.

You can find these types of dowels here

To help you find the optimum solution for your project, here is an overview of the most important anchor types:

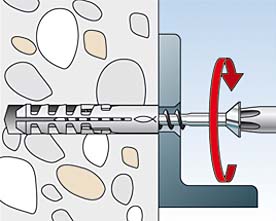

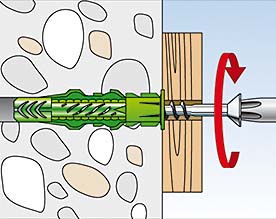

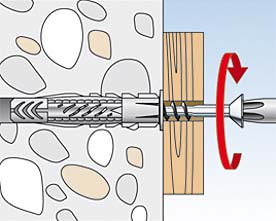

- Expansion and screw anchors: For standard applications in solid building materials. When the screw is screwed in, the plug expands and holds securely in the masonry.

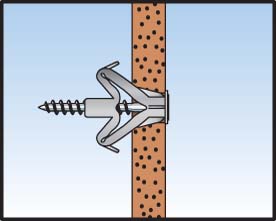

- Cavity plugs: Specially designed for fixing in plasterboard, drywall and hollow ceilings. Thanks to their design, they provide a secure hold despite the low wall thickness.

- Frame anchors: For through-penetrated fixings - for window frames or mounting plates, for example. Ideal for solid building materials such as concrete or solid brick.

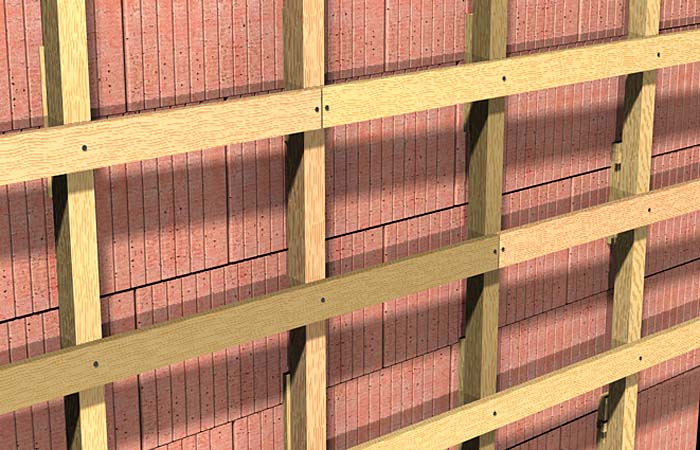

- Insulation anchors: These special anchors are designed for installation in insulating materials without impairing the insulation performance.

- Heavy-duty anchors and bolt anchors: For the highest loads in concrete or brick. They are used for heavy-duty fastening, e.g. of beams or large lights.

- Chemical fixing: Composite mortar, injection mortar and matching anchor rod are used to create an extremely resilient connection - ideal for high loads or critical building materials.

What is important when choosing?

Several factors are decisive when choosing the right anchor:

- Type of building material: concrete, aerated concrete, brick, plasterboard or insulation boards - each material has different requirements. You need different wall plugs for masonry than for cavities or insulating materials.

- Fastening technique: Whether you drill, screw or inject - the technique must match the anchor and the application.

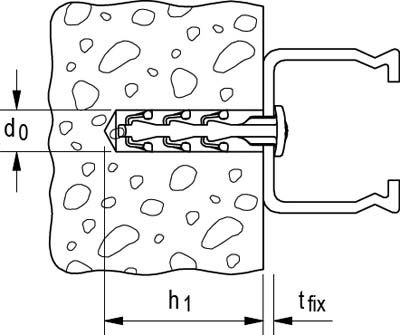

- Drilling diameter and drilling depth: Pay attention to the manufacturer's specifications, as the drilling diameter and length of the drill hole have a significant influence on the holding force.

- Load and load-bearing capacity: For heavy loads, you need heavy-duty anchors, heavy-duty plugs or chemical plugs. Standard plastic plugs are often sufficient for lighter loads.

- Installation environment: Different requirements apply indoors than outdoors. For damp or aggressive environments, brass anchors or stainless steel anchors are the right choice, for example.

Your advantages at WATT24

- Versatile range: From cavity wall plugs to chemical heavy-duty fasteners - you'll find what you need here. - Fast delivery: Many anchor types are immediately available from stock.

- Expert advice: Not sure which anchor is right for your wall material or fixing? We'll be happy to advise you.

- Quality products: High-quality wall plugs from proven manufacturers - for maximum load-bearing capacity and durability.

Find the right anchor for your project now - tailored to the building material, load and fastening technology. If you have any questions or special cases, we will be happy to advise you.

FAQ: Frequently asked questions about dowels

How is a dowel used?

Dowels are used in many DIY and construction projects. If you need to use dowels, the first step is to drill the hole at the point where the object is to be anchored later. Also note that the size and length of the drill hole depends on the type of dowel you choose. Once the hole has been drilled, you should thoroughly remove the drilling dust, for example with a vacuum cleaner or bellows. Only if the hole is clean can the plug be firmly secured later. You can then insert the plug into the drilled hole. This is usually easy to do with your finger. Make sure that the plug is flush with the wall. It can also easily sink into the wall. You can also use a hammer-in anchor for heavy objects. Insert this into the drill hole and then hammer it in with a setting tool. This allows the anchor to expand evenly and securely for firm anchoring in the wall. Once the anchor or dowel has been placed in the wall, you can attach your object to the wall.

What types of dowels are there?

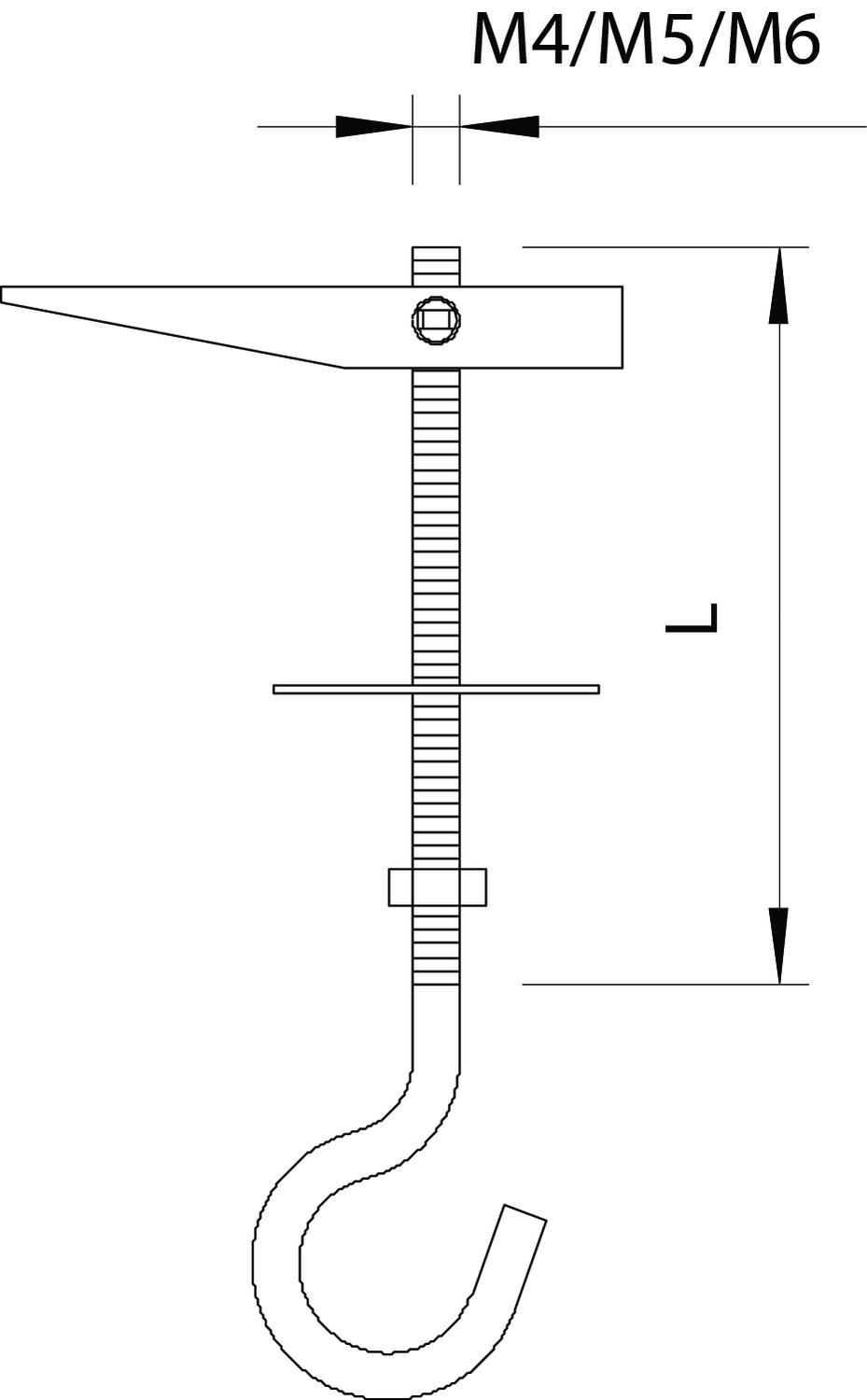

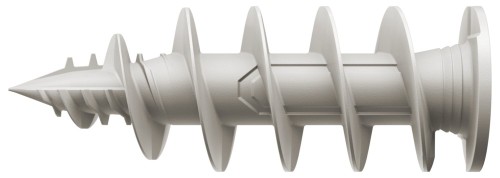

There are many different types of dowel. The most common types of dowels are expansion dowels, tilt dowels, chemical dowels, plasterboard dowels, impact dowels, gas concrete dowels, standard dowels, nail dowels, universal dowels, cavity dowels, spring-loaded dowels, long-shaft dowels, plastic dowels and metal expansion dowels. But heavy-duty dowels, wooden dowels, panel dowels, frame dowels, aerated concrete dowels and insulation dowels are also popular.

What is a standard anchor and what is a special anchor?

Standard dowels are usually dowels that are also known as expansion dowels or universal dowels. They are used for various installation tasks as they are also suitable for a variety of substrates. These include solid bricks, hollow bricks, concrete and plasterboard. Special anchors, on the other hand, are intended for specific applications or materials. Plasterboard plugs, for example, are special plugs and are intended for plasterboard and plasterboard walls, which are particularly brittle and not so strong. But there are also specific dowels for gypsum fiberboard or other panel building materials, such as gypsum fiberboard dowels, panel dowels or direct fastening dowels.

What heavy-duty fixings are available?

Both chemical dowels and metal heavy-duty dowels are suitable for heavy-duty doweling. However, concrete screws, threaded anchors, steel anchors such as bolt anchors, roof anchors and façade anchors can also be used when it comes to fastening heavy loads and components.

How do insulation plugs work?

Insulation anchors or thermal anchors are used to attach insulation materials. This allows the insulation materials to be mounted on walls and ceilings to improve thermal insulation. To do this, a hole is drilled into the insulation board and the masonry. The drill hole depth must exceed the thickness of the insulation board and also meet the required anchoring depth in the masonry. The insulation plug can then be inserted into the pre-drilled hole. The length of the plug should extend through the insulation and deep enough into the masonry for stable anchoring.

.png?ts=1748345539)